Currently, there are three assembling technologies used in the synthetic ice rink industry:

Dovetail Spline Square Edge

A dovetail joint is a technique that has been commonly used originally in woodwork for thousands of years.

The Dovetail Interlocking Technique became very popular in synthetic ice rink installation after more and more successful synthetic ice rinks were installed by Global Synthetic Ice. GSI has been concentrating efforts on installation methods since the 1990s, and eventually created a successful method to build even full-size outdoor facilities using that technology.

The revolutionary new patented assembly method used on Super-Glide synthetic ice panels is the result of 25 years of experimentation in real-life situations; it solves all the problems that hindered the construction of a successful ice rink. Designed to control expansion, it allows any size rink to be built inside or outside. This new installation method allows panels to be installed seamlessly in significantly less time than with prior systems!

Currently, Global Synthetic Ice uses patented Super-Glide dovetail interlocking technology with 55 connection points to create a seamless surface. Another benefit of dovetail technology is the simplicity of assembling with the use of just a rubber mallet. Even outdoor Super-Glide synthetic ice rinks successfully work all year round providing a seamless ice-skating surface for the best and safe skating experience.

Outdoor all-year-round community ice rink in Algarve, Portugal with Super-Glide SLICK synthetic ice successfully operating since 2020

Full NHL size ice rink with Super-Glide synthetic ice, Canada Public outdoor ice rink with Super-Glide SLICK synthetic ice in Ukraine

Full NHL size ice rink with Super-Glide synthetic ice, Canada Public outdoor ice rink with Super-Glide SLICK synthetic ice in Ukraine

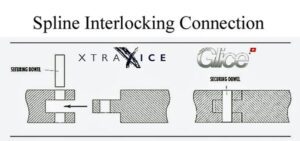

Spline panels have been in circulation for many years, and although the spline connection is successful at preventing vertical separation of panels, there is little to no protection against horizontal separation, that is why, especially on larger ice rinks, you can see seams.

The pegs (securing dowels) are often break and sometimes it is very hard to get them out. Since pegs are often made from different type of plastics and that they are small comparing to the panel, they expand and contract differently. As the result some pegs even move up from the vibration of skating.

Hockey and figure skating maneuvers, as well as temperature variations will separate these panels very fast.

This technique has been a hardly used system for many years.

UNDERLAYMENT / SUBFLOOR

Designed to eliminate possible imperfections of the surface on which a synthetic ice rink is installed. In addition, it is necessary to ensure unhindered contraction/expansion of synthetic ice panels during temperature fluctuations. This is especially important with outdoor rinks.

Super-Glide Substratum Panels are recommended for outdoor installations. Specially designed hard polymer panels are laid under the Super-Glide surface and designed to allow the Super-Glide to expand and contract with changing temperatures, also helps with minor imperfections in the ground surface.

Super-Glide Substratum Panels

Some suppliers use plywood panels, rubber mats, soft foam rolls, etc. for underlayment.

Plywood sheets

Rubber Mats

Plywood panels are not suitable for outdoor ice rinks as they absorb moisture, swell, and push the panels out.

Rubber mats and soft foam rolls are not good either as they are not hard enough.

THE SUCCESS OF ANY SYNTHETIC ICE RINK DEPENDS ON THE QUALITY OF GLIDING AND THE RELIABILITY OF INSTALLATION